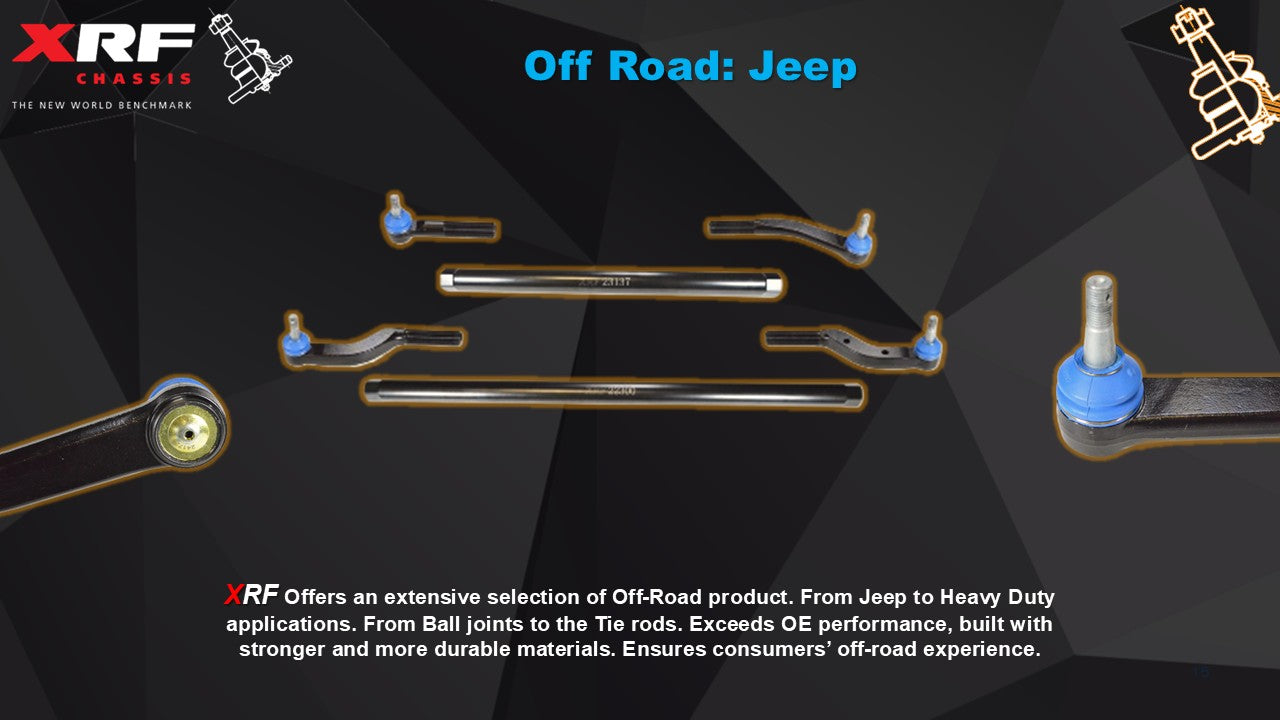

XRF Heavy Duty Left Driver Side Lower Outer Tie Rod End, Jeep 2020-2025 Jeep Gladiator JT, 2018-2025 Wrangler JL

XRF Heavy Duty Left Driver Side Lower Outer Tie Rod End, Jeep 2020-2025 Jeep Gladiator JT, 2018-2025 Wrangler JL

- Million-Mile Limited Lifetime Warranty

- Free Shipping

SKU:XTJ103P

Couldn't load pickup availability

Gladiator JT 2020, 2021, 2022, 2023, 2024, 2025

Wrangler JL 2018, 2019, 2020, 2021, 2022, 2023, 2024, 2025

XRFs 2.5 ton upgrade provides increased strength, durability, and improved steering response, almost tripling the durability.

Step up to XRF's Legendary Durability. Do not waste time and money on inferior parts. Do it once and do it right with XRF. Includes a Million-Mile Limited Lifetime Warranty to the original purchaser. Warranty is limited to normal wear and tear and manufacture defects.

Safety - Durability - Reliability

Every XRF part is made exactly to specifications with “zero tolerance” variations. Our competitors cold forge their shells and allow large tolerances for die wear allowing the possibility to have some parts too tight and others fit too loosely at the press fit diameter.

These parts are built like anti-friction bearings with close tolerances and highly polished studs. Using high strength step thread on all the ball studs and nuts. This is a matched thread that allows the installer to spin the nut on by hand but when torqued, it provides the strongest thread available.

XRF’s hot forging process improves the mechanical properties of the metal. This efficiency is particularly important when working with expensive materials, such high-grade steel. It also provides excellent consistency and repeatability in the production of parts. The hot forging process reduced waste generation also contributes to lower environmental impact.

XRF uses many features to give us the most ‘Reduced Friction’ parts on the market. This all adds up to smoother steering, better handling and increased fuel efficiency. In addition, XRF had added many installer focused features aimed at reducing install times.

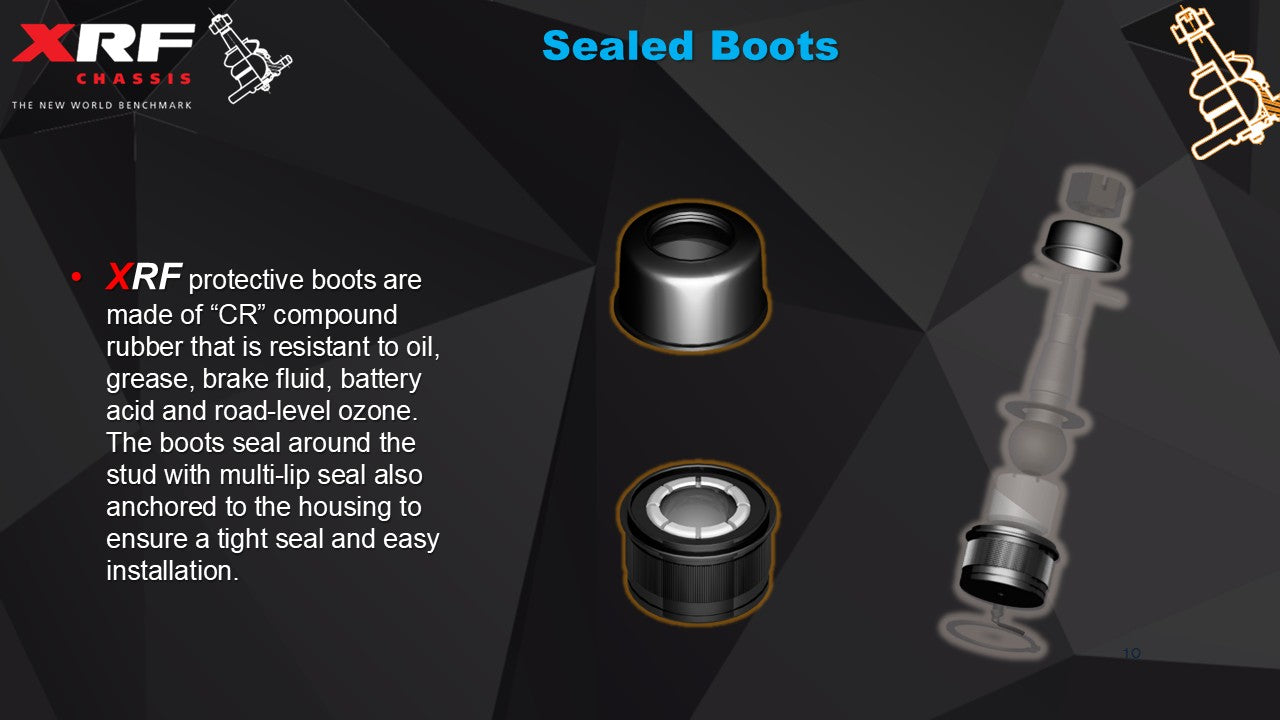

Protective boots are made of “CR” compound rubber that is resistant to oil, grease, brake fluid, battery acid and road-level ozone. The boots seal around the stud with multi-lip seal also anchored to the housing to ensure a tight seal and easy installation.

Upgraded Chloroprene Rubber Duster Covers: Anti-ozone Test, Heat and Oil Resistance.

Benefits: Extended lifespan and reduced maintenance needs. Exceptional performance and reliability.

Upgraded High-Strength Composite Material Bearings: Precision Design for High Durability.

Premium Cohesion & Lubricity Grease: Pre-packed for Optimal Performance.

Benefits: Unmatched strength and durability. Enhanced corrosion resistance.

Upgraded High-Strength Carbon and Alloy Steel Nuts: ASTM A563M Class 10 & SAE J995 Grade 8.

Benefits: Improved heat and oil resistance. Smooth operation and reduced wear.

Upgraded High-Strength Alloy Steel Ball Joints: ASTM Salty Spray for Special Coating Treatment.

Upgraded High-Strength Carbon Steel Housing: ASTM Salty Spray for 240 Hours.

Replaces TR182, 68309365AE, 68258761AE

WARNING: Cancer and Reproductive Harm -- www.P65Warnings.ca.gov

WARNING: Cancer and Reproductive Harm -- www.P65Warnings.ca.gov